DIMENSIONAL CONTROL

When your products must adhere to strict manufacturing standards in terms of diameter, thickness, angle, length, and height, regular dimensional and compliance checks are essential. However, manual inspections are often time-consuming and prone to errors. To save time, enhance efficiency, and ensure increased accuracy, it's time to move away from manual dimensional measurement systems and trust in our industrial vision systems.

Our industrial vision systems incorporate cutting-edge 2D and 3D technologies, enabling continuous monitoring of your product dimensions. Relying on these advanced technologies, you can streamline your inspection processes, improve efficiency, and ensure your products comply with manufacturing standards.

Dimensional control examples

In the consumer goods industry, packaging quality and product integrity are of paramount importance. We understand the significance of ensuring secure and compliant packaging. That's why our 2D vision sensors are specifically designed to swiftly and accurately measure the dimensions of packaging tamper seals (height, width, positioning).

With our advanced technology, we can perform these measurements in minimal time, ensuring the integrity of your packaging. Seals that do not meet predefined standards are identified and removed before products are cartoned at the end of the production line. This proactive approach significantly reduces the risk of product recalls and allows you to maintain packaging quality.

Trust in our 2D vision sensors to guarantee the security and compliance of your packaging in the consumer goods sector.

Industrial applications examples

Automotive

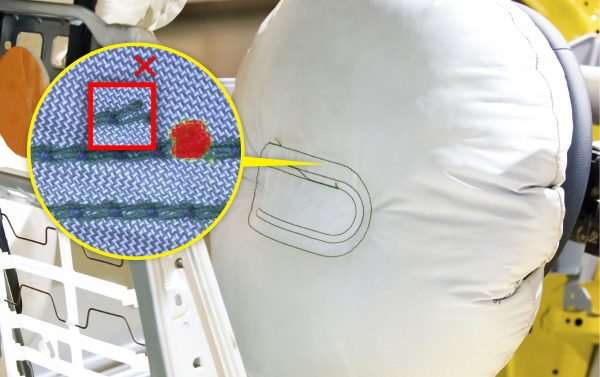

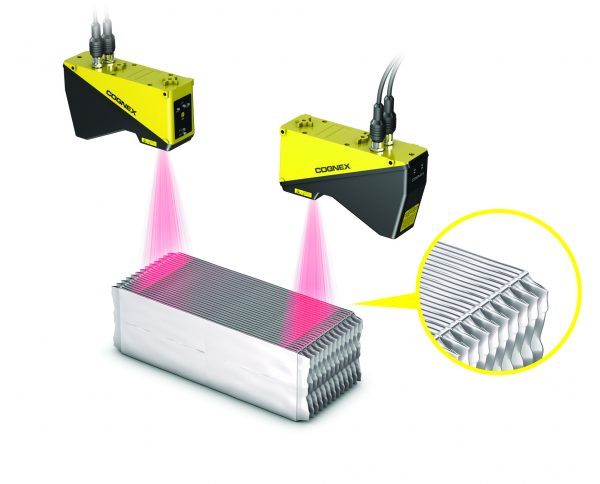

In the automotive sector, numerous measurements can be performed using vision sensors. This includes verifying the dimensions of airbag components (seam length and their positioning) or measuring the profiles of stacked batteries in electric vehicle modules, made precise and swift through 3D laser displacement sensors.

BEVERAGE INDUSTRY

In the beverage industry, bottle inspection must occur on very fast assembly lines, leaving little time for comprehensive checks using traditional methods. Our vision systems can deliver visual inspection tailored to the production pace: equipped with contour detection technology, these vision systems accurately and rapidly measure the distance between the top of the cap and the bottle neck to ensure proper positioning and sealing, ensuring the final product meets production standards. Sorting out incorrectly assembled bottles is done in advance: as soon as they're detected, they are removed from the line before packaging and shipment.

PHARMACEUTICAL

In the pharmaceutical industry, ensuring the correct assembly of intricately shaped objects like syringe needles is a continuous challenge that demands constant vigilance. It's a challenge our vision systems address by measuring the positioning, straightness, and other characteristics of syringe safety devices. Industrial vision solutions paired with Deep Learning also enable dimensional inspection of the needle itself, determining the inner and outer diameters of its tip.

In short, no need for product recall with these vision solutions!