Deep Learning Solutions in Industrial Vision

Industrial vision systems integrating Deep Learning technologies offer fast and efficient automation of various operational tasks. They enable product classification, location tracking, assembly verification, optimized code reading (OCR), and defect detection (both aesthetic and surface, even on reflective materials), as well as contamination detection.

ViDi Deep Learning, based on neural networks, is a widely used machine learning method. It's employed for voice, text, and facial recognition in mobile and wearable devices. Operating on a predictive model, this technology collects and analyzes data to deduce future trends. When combined with industrial vision, it equips manufacturing technologies with new identification capabilities in complex visual environments. ViDi's Deep Learning models can detect defects in products with multiple appearance variations. They're also flexible and easy to adapt to new examples without requiring algorithm reprogramming.

ViDi Deep Learning solutions examples

When it comes to inspecting complex objects like spot welds, which are three-dimensional structures with significant variability in appearance, traditional industrial vision techniques can fall short. In such cases, solutions based on ViDi Deep Learning offer an effective alternative. By mimicking the workings of the human brain, these solutions use software capable of identifying details on metal parts, even when their dimensions vary slightly. By comparing images of defective spot welds to those without defects, a Deep Learning-based inspection application can quickly learn and streamline the manufacturing automation process. Through this approach, it becomes possible to detect and classify weld defects with increased precision, thereby enhancing the quality and efficiency of production

Industrial applications examples

CONSUMER GOODS

Lecture of Codes on Flexible Packaging

Today, the majority of consumer products are transported in flexible packaging such as sachets or gusseted pouches, complicating code reading. Each package must display a printed date/lot code and tracking information. Reading codes on these flexible and intricate surfaces requires the use of vision solutions based on ViDi Deep Learning, as Optical Character Recognition (OCR) technologies alone are insufficient. An Optical Character Recognition tool enhanced by Deep Learning can read printed codes, even on flexible surfaces, and train to read distorted and asymmetric texts.

Defaut Detection on Complex Surfaces

ViDi's Deep Learning vision solutions also cater to the needs of razor manufacturers. The blades of an electric razor have a reflective, perforated mesh with numerous holes, making defect detection impossible for traditional industrial vision. However, ViDi's Deep Learning-based industrial vision systems learn to distinguish between acceptable variations and defects, successfully detecting flaws even on reflective and complex surfaces.

FOOD

Products with Variations in Appearance Inspection

This is the case with pizzas, which can exhibit subtle variations in appearance. In this highly competitive food market, manufacturers must produce large quantities of symmetrical, uniform pizzas while minimizing material waste. On high-speed production lines, several criteria need inspection: pizza type, correct number and distribution of various ingredients, and absence of contaminants. However, with conventional industrial vision systems, these appearance variations are too subtle to detect. Hence, manufacturers benefit from turning to ViDi Deep Learning-based vision solutions to automate product inspection and ensure optimal ingredient distribution.

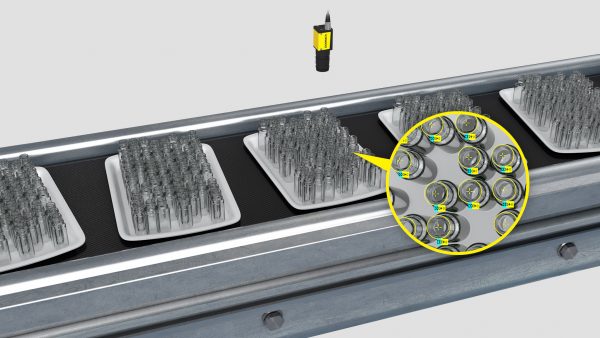

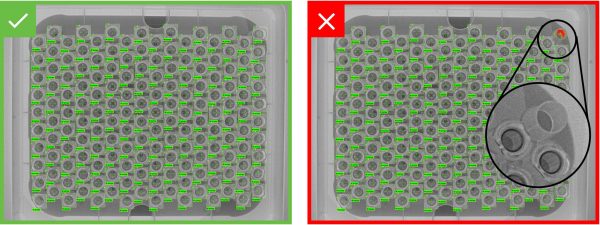

Pharmaceutical

Automated counting of glass vials and ampoules faces similar challenges. The fisheye effect (image distortion) hinders traditional industrial vision systems from accurately verifying the correct positioning of reflective products. However, Cira and Cognex's ViDi Deep Learning-based vision solutions can reliably identify errors such as falls, overturns, and product mix-ups through sophisticated image analysis (e.g., incorrect cap colors on containers). This facilitates the counting of vials and ampoules, enhancing operational efficiency in the industry. These solutions are trained to identify errors on objects placed at all possible angles, successfully detecting them despite the fisheye effect.

The camera equipped with HDR+ (High Dynamic Range Plus) technology plays a direct role in this performance: it provides a clear and uniform image from a single capture of moving parts. It differs from standard HDR technology, which requires capturing multiple images to achieve the same level of accuracy. By enabling simultaneous processing of a large volume of vials and ampoules, these ViDi Deep Learning-based vision solutions contribute to a reproducible counting method.

AEROSPACE

The fight against counterfeit products concerns numerous industries, including the aerospace sector. To ensure precise traceability of parts throughout the manufacturing chain, DPM (Direct Part Mark) characters are placed on machined metal parts. However, because they are made from the same material as the part, these characters are difficult to distinguish from the substrate onto which they are etched. This low level of contrast makes reading through conventional industrial vision very challenging. Hence, Cira proposes integrating ViDi Deep Learning solutions combined with OCR (Optical Character Recognition) technology, which have no issue reading raised codes.

AUTOMOTIVE

On automotive assembly lines, there are often multiple ranges and models of engines that vary in size and composition. The engine constitutes a complex background that makes component identification challenging. Moreover, customization is increasingly common and amplifies the variations in appearance among different engines. When these variations are significant, programming conventional industrial vision systems becomes challenging. ViDi Deep Learning-based vision solutions are trained on all possible types of engines and assemblies. The classification tool manages to identify each component, regardless of the angle at which it is presented. These solutions easily adapt to any potential design changes.

Detection of defects on reflective metal surfaces

Detecting defects on compression segments is challenging due to the reflective surface of pistons. Inspection systems must distinguish between acceptable variations (rust, small cracks) and severe defects that directly impact compression levels (long scratches). The complexity of this inspection, with reflective surfaces and variations in defect appearance, makes programming classical industrial vision systems lengthy and tedious. On the other hand, Deep Learning ViDi detection tools quickly learn to identify only unacceptable defects on pistons, ignoring insignificant variations.