The guidance of robots

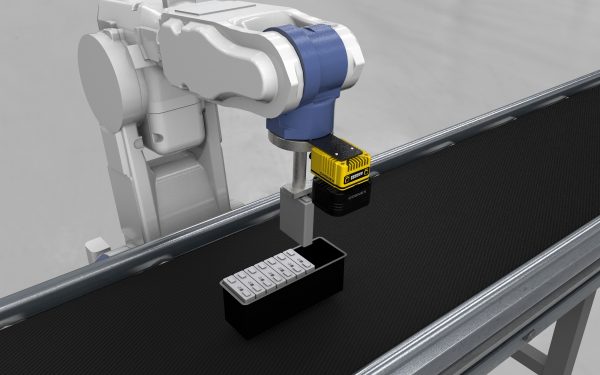

When it comes to module insertion machines, manual programming often consumes a lot of time and poses a high risk of errors. However, the use of robots guided by 2D vision technology for repetitive or hazardous tasks offers advantages in terms of efficiency, precision, and safety. Robots equipped with this technology can perform assembly and product handling tasks, regardless of their size or shape, significantly enhancing robot-assisted manufacturing.

3D industrial vision systems play an even more significant role in simplifying and improving robot-assisted manufacturing. Through 3D vision-guided robotics, it is now possible to automate tasks that were previously impossible to achieve and required a high degree of precision, such as welding. Cognex vision systems result from a close partnership with leading robot manufacturers, allowing us to integrate our solutions into a wide range of industrial robots. Thus, our vision technology provides advanced automation opportunities to enhance the efficiency and precision of manufacturing processes.

Example of robot guidance using industrial vision

Vision-guided robots are employed for the selection and packaging of food products. Through a vision system, they can discern the shapes, sizes, colors, and textures of products, enabling accurate selection along the production line. Sorting becomes challenging due to slight variations between products. However, industrial vision technology identifies and communicates the product's position on the conveyor to the robotic arm. The robot arm utilizes this information to pick up the product and place it in its appropriate packaging.

Industrial applications examples

Automotive

Every step in the vehicle assembly process can benefit from robotics through industrial vision. For instance, our vision systems guide robotic arms for precise locating and tightening of wheel nuts. 3D vision systems also come into play during the inspection of body panels, providing real-time data to guide robots to the correct parts on racks.

The lithium-ion battery modules of electric cars are assembled to form a block using connectors and fasteners. The palletization step (stacking of modules) requires the intervention of vision-guided robots to pick, manipulate, and place the batteries into bins before they are connected and charged.

ELECTRONICS

Vision-guided robot guidance enables high-quality and precise assembly of various electronic products. For example, our vision systems guide robotic arms for the precise alignment of batteries in mobile and portable devices. Vision-guided robots also play a role in the production and lamination of OLED screens: vision systems assist autonomous robots in locating a piece, gripping it, and then placing it in test areas for programming. Our solutions address multiple calibration challenges, from the accurate localization of parts to their final positioning by robots. As a result, final assemblies no longer require any manual intervention.

COSMETICS

3D vision-guided robot guidance is a crucial asset in the cosmetic industry, offering improved precision and increased productivity. By accurately detecting the position and orientation of objects, it facilitates the picking, placing, and assembly of products. Moreover, this technology allows for flexibility and adaptability by recognizing various types of packaging. It also reduces labor costs by automating repetitive tasks, thereby optimizing operational efficiency.

Regardless of the industrial sector involved, vision-guided robot guidance contributes to high-quality assemblies completed within a limited time frame.